ToolingShuttle 30

Change crimp applicator (tooling), terminal reel and paper winder in less than 60 seconds with Plug & Crimp™.

The ToolingShuttle 30 can be prepared for the next job at an external workstation while the machine is producing thereby reducing machine downtime to a minimum. Once in position the applicator is quickly moved from the ToolingShuttle and secured into the crimping station.

The ToolingShuttle 30 accepts all standard crimping tools (mini-style applicators), so existing applicators can be easily integrated.

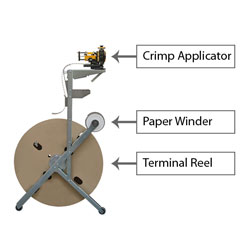

ToolingShuttle 30 (fully equipped)

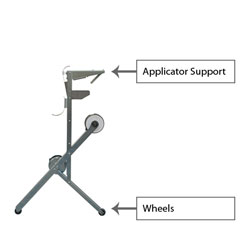

ToolingShuttle 30 (fully equipped) ToolingShuttle 30 (base frame)

ToolingShuttle 30 (base frame) Plug & CrimpTM Technology

Innovative Plug & Crimp technology lets operators exchange ToolingShuttles on CrimpCenter series machines in the shortest possible time – without any additional tools.

The ToolingShuttle 30 is a sturdy lightweight construction equipped with 2 wheels and 2 handles for optimum maneuverability.

Options

- ShuttleRack: mobile storage rack for up to 5 ToolingShuttle 30 units

- Automatic identification of individual ToolingShuttle 30 units with barcode

Technical Specifications

| Attribute | Value |

| Length | 660 mm (with terminal reel)* (26.0”) |

| Width | 140 mm (5.5”) |

| Height | 1107 mm (with crimp applicator)* (43.5”) |

| Weight | Base frame: 7 kg (15.4 lbs) Fully equipped: 11.5 kg* (25.3 lbs) |

| CE-Conformity | The ToolingShuttle 30 fully complies with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |

* Dimensions and weight may vary depending on type of crimp applicator, terminal reel and paper winder.